Hydroponic Chiller

Introduction

Hydroponic water chiller is a device used in a hydroponic garden to remove heat from the mineral-rich water solution, through an absorption refrigeration cycle. It facilitates a heat exchange process that ensures that the temperature of the nutrient solution remains ideal for plant growth.

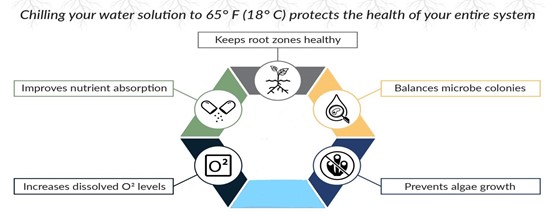

Hydroponic gardening is aquatic based, and it depends solely on the use of water and mineral-rich solutions. When the temperature of water becomes excessively high, then the growth of plants is subsequently inhibited. High temperatures reduce the much-need oxygen around the root zone, leading to stunted growth. This is where the use of a hydroponic water chiller comes in handy. A water chiller keeps temperatures within an optimum range, ensuring that the nutrient solution can hold dissolved oxygen much longer until it is accessible to the root zone.

Considering the increased oxygen levels, and a pathogen-free environment, the chances of reaping higher yields from your hydroponic garden are very high. Water chillers are essential in creating a favorable environment for your plants to thrive.

Strengthens the plant roots and stems improves taste of fruits and vegetables better yield of crops, vegetables and fruits increases nutrient content in produce.

It does not require much space, and it allows plants to grow up to 50 % faster. Adding a water chiller to a hydroponics system will help you realize even more benefits.

Designed for large-scale hydroponic grow rooms, hydroponic chillers from  can achieve the close temperature control required for optimal plant growth.

can achieve the close temperature control required for optimal plant growth.

This is where the use of a hydroponic water chiller comes in handy.

Advantage

High oxygen levels- Water chillers provide the cool temperature necessary to hold increased quantities of dissolved oxygen.

Higher root growth and increased nutrient absorption- this is a direct result of increased oxygen levels.

Decreased risk of harmful pathogens- Highly oxygenated, cool environments prevent the growth of pathogens that could damage plants.

Adaptable- no matter what your setup (ebb and flow, drip, nutrient film technique, etc.), a chiller can easily be incorporated into your system

More precise control- compared to other cooling methods, water chillers offer more precise control. They can often be set to specific temperatures.

Require less time and work- once it’s set up, utilizing a water chiller is often as easy as flipping on a switch.

Product Information

l Designed for greenhouse growing

l Delivers industrial-grade comfort cooling

l Uses environmentally safe fluids

l Magnetic Water treatment device

l Configurable heat recovery system to save energy

l Equipped with magnetization device to improve the quality of nutrient solution, promote plant root development and nutrient absorption

l No need for cooling water system and dedicated machine room, saving construction space and investment cost

l Chiller Application: Green vegetables, tomatoes, cucumbers, herbs and hemp

Model | OP-2800ACC | OP-5600ACC | OP-8400ACC | OP-14000ACC | |

Power Supply | 1PH/220V/50Hz | 1PH/220V/50Hz | 3PH/380V/50Hz | 3PH/380V/50Hz | |

Cooling Capacity | KW | 2.8 | 5.6 | 8.4 | 14 |

Rated Input Power | KW | 1.2 | 1.98 | 2.87 | 4.88 |

Dissipate Heat Air Flow | m3/h | 1000 | 2000 | 3000 | 5000 |

Water Flow | m3/h | 0.6 | 1.2 | 1.8 | 3 |

Water Head | m | 10~15 | 10~15 | 15~20 | 15~20 |

Temperature Control Range | ℃ | 5℃~25℃ | |||

Temperature Control Accuracy | ℃ | 2℃ | 2℃ | ±1 | ±1 |

Control Mode | Intelligent microcomputer control board, control equipment operation and temperature display | ||||

Water Tank | L | 15 | 30 | 50 | 70 |

Net Weight | Kg | 70 | 90 | 160 | 220 |

Net Dimension (L*W*H) | mm | 610*420*850 | 630*500*910 | 1050*500*1050 | 1150*580*1150 |

Remark: Nominal cooling conditions: outdoor environment dry bulb temperature 35°C, wet bulb temperature 24°C, inlet water temperature 12°C, outlet water temperature 7°C. Nominal heating conditions: outdoor environment dry bulb temperature 7°C, wet bulb temperature 6°C, inlet water temperature 40°C, outlet water temperature 45°C. | |||||