Related Products

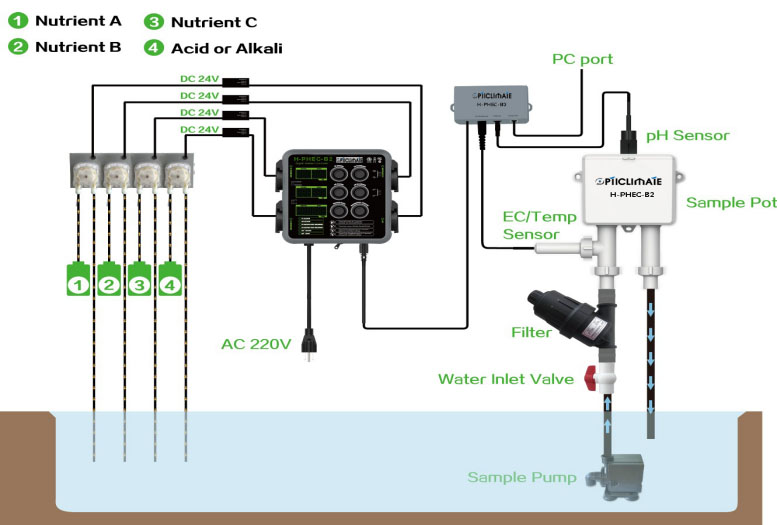

◆ EC nutrient solution detection and control. Automatic detection of nutrient solution and automatic ratio, automatically obtain nutrient solution concentration balance.

◆ PH nutrient solution detection and control. The PH of the nutrient solution is automatically detected and matched, and the PH of the nutrient solution is automatically balanced.

◆ Temperature detection and control. Automatic detection of nutrient solution temperature.