Product Description

IDEC(Hybrid)

l The compressor system is added to IDEC.

l Energy saving air conditioner applied in a wider environment.

In dry and semi humid climates, stand-alone IDEC performs very well.

However, in humid climates, the IDEC (Hybrid) cooling units can be complemented by a compressor refrigerant system to achieve the desi red comfort conditions.

This hybrid approach results in a great deal of energy saving over a stand-alone compressor-based system and the whole system is controlled by the joint control system.

Working Principle

Around the world where evaporative cooling has been limited, hybrid systems incorporate traditional refrigerant or chilled water-cooling coils to work in conjunction with one another and provide hybrid systems without compromise.

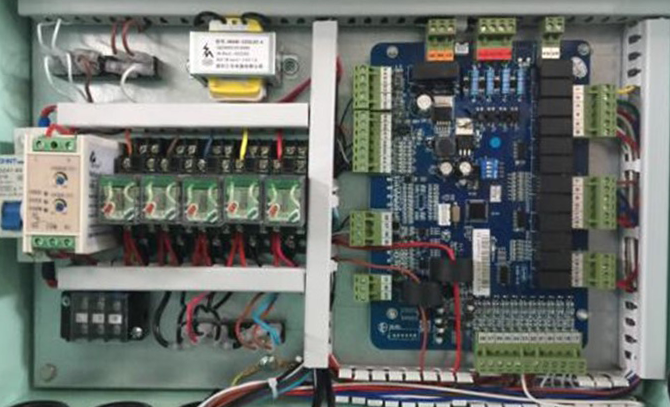

Combines two stage evaporative cooling system with an integrated compressor system. Utilizing Hicool’s unique joint control system, continuously adapting cooling strategy to run only the most efficient cooling systems for the ambient condition of the moment. Ensuring consistent performance, high efficiency and significant energy savings.

Working Modes

1. Dry / Semi-Dry season: Direct + Indirect evaporation.

2. Humid / Semi-Humid season: Compressor system.

3. In extreme conditions: Direct + Indirect evaporation + compressor system.

Product Features

l According to environmental requirements, through the automatic control system, it can accurately predict system performance and energy consumption.

l Energy saving up to 50%.

l Suitable for high temperature areas, avoiding the inability of normal air conditioners or high energy consumption due to high temperature.

l Healthy free control of 100% fresh air, without extra cooling load.

l Patented product (patent No. ZL 2013 1 0411456.2)

Application Range

Suitable for all areas where only cooling is required, especially high temperature and dry areas.

Product Information

IDEC Hybrid Series

The compressor system is added to IDEC, with all the advantages of IDEC.

Combines two stage evaporative cooling system with an integrated compressor system to work in conjunction with one another and provide hybrid systems.

According to environmental requirements, through the automatic control system, it can accurately predict system performance and energy consumption.

Outdoor applications for wider areas, and even for extreme environment with strict requirements.

It is especially suitable for greenhouse planting, commercial sites, industrial sites, and open buildings in high-temperature areas.

Model | FAO2- 50(Hybrid) | FAO2- 125(Hybrid) | FAO2- 250(Hybrid) | |

Power Supply | 220V~1N~50/60Hz | 380V~3N~50/60Hz | 380V~3N~50/60Hz | |

Cooling Capacity | USRT | 5RT+3RT | 12.5RT+9RT | 25RT+20RT |

KW | 17.5KW+10.5KW | 43.75KW+31.5KW | 87.5KW+70KW | |

Air Flow | CFM | 2500 (4250m3/h) | 5000 (8500m3/h) | 10000 (17000m3/h) |

Rated Input Power | KW | 3.42 | 9.07 | 18.57 |

EER | 8.18 | 8.29 | 8.48 | |

Refrigerant | HFO-1234yf /R417A/R410A/407C etc. | |||

External Static Pressure | Pa | 120 | 300 | 350 |

Water Pressure | Mpa | 0.2~0.6 | 0.2~0.6 | 0.2~0.6 |

Noise | dB(A) | ≤70 | ≤75 | ≤80 |

Protection Grade | II | II | II | |

Water Proof Class | IP×4 | IP×4 | IP×4 | |

Water Consumption | L/H | 40 | 100 | 185 |

Net Weight | kg | 320 | 700 | 1300 |

Gross Weight | kg | 345 | 725 | 1330 |

Net Dimension (L×W×H) | mm | 1600×1120×1200 | 2900×1700×1510 | 2900×1700×2300 |

Packing Dimension (L×W×H) | mm | 1620×1140×1320 | 2920×1720×1630 | 2920×1720×2420 |