Hicool's Willingness to Develop Climate System

—— Providing Greenhouse Climate Solutions

The goal of Hicool is to develop products that can achieve the best performance in all areas. Our independently developed OptiClimate Air Conditioner Unit (Optical&Humidity Induction Control) series of water-cooled air conditioners is a complete solution that is truly used for indoor climate control and perfectly controls the indoor climate with the lowest energy consumption.

Parameters

OptiClimate Split Unit (Optical&Humidity Induction Control)

Capacity:1TR - 45TR(3KW - 160KW)

Opticlimate Split Unit Parameter |

Model | 21000 PRO4 Split |

Cooling Capacity | kW | 21 |

Cooling Capacity | BTU | 71590 |

Electrical Heater | kW | 2×3.0 |

Rated Input Power | Cooling | kW | 6.9 |

Rated Input Current | Cooling | A | 10.5 |

Indoor Unit |

| Power Supply | 220V / 50Hz / 1P |

Rated Air Flow Volume | m3/h | 4000 |

Fan Motor Power | kW | 0.22×2 |

Fan Motor Input Current | A

| 2.2 |

| Static Pressure | Pa | 70-200 |

| Noise | dB(A) | 56 |

| Net Dimension(LxWxH) | mm | 1600×600×435 |

Net Weight | kg | 73 |

| Packing Dimension(LxWxH) | mm | 1540×658×495 |

| Gross Weight | kg | 91 |

| Outdoor Unit |

| Power Supply | 380V/3P/50Hz |

| Compressor | Qty | 1 |

Type | Scroll compressor |

| Refrigerant Charge | kg | 4.5 |

| Refrigerant | R417A/R407C/R410A |

| Connecting Pipe | Liquid | Inches | 1/2" |

Gas | Inches | 3/4" |

| Maximum Piping Length | m | 40 |

| Maximum Height Drop | m | 10 |

| Air Discharging Type | Top |

| Noise | dB(A) | 62 |

| Net Dimension(LxWxH) | mm | 1250×640×1010 |

Net Weight | kg | 150 |

Packing Dimension(LxWxH) | mm | 1296×735×1110 |

Gross Weight | kg | 188 |

Note:

Nominal cooling conditions: indoor dry bulb temperature is 27℃, indoor wet bulb temperature is 19℃, outdoor dry bulb temperature is 35℃, outdoor wet bulb temperature is 24℃. |

Product Description

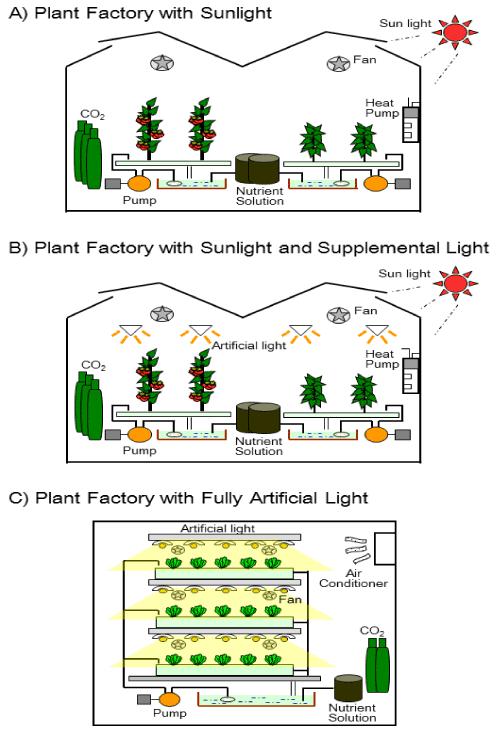

Hicool—The plant factory is a closed-growth system that uses artificial conditioning to control the environmental conditions required for plant growth: light, temperature, humidity, CO2, nutrient solution, enabling crops to be produced all year round.

Black Room Tent

Crops in plant factories are not affected by climate change and bacteria and pests, and Hicool's specially developed nutrient solution for each crop allows the crop to have consistent quality and yield.

Closed Environment

Nutrient Solution Development

Guarantee for the production of high-quality crops: sterile, free of heavy metals and other toxic substances.

- No pest intrusion, no pesticide spraying.

- No soil environment, no bacterial residue.

Soilless Cultivation

The hydroponic cultivation method allows crops to be continuously planted. In addition, by controlling light intensity, temperature, humidity and carbon dioxide concentration, the crop is grown in the most ideal environment to maximize yield.

Continuous Planting

According to the growth characteristics of plants, the vertical growth method is used to carry out crop cultivation at the maximum density, and the land use rate is greatly improved.

Vertical Planting

Standardization of cultivation techniques,You can participate without professional agricultural knowledge. In addition, because the workflow is simple, both the elderly and the disabled can be qualified for the daily work of the plant factory.

Standardized Planting

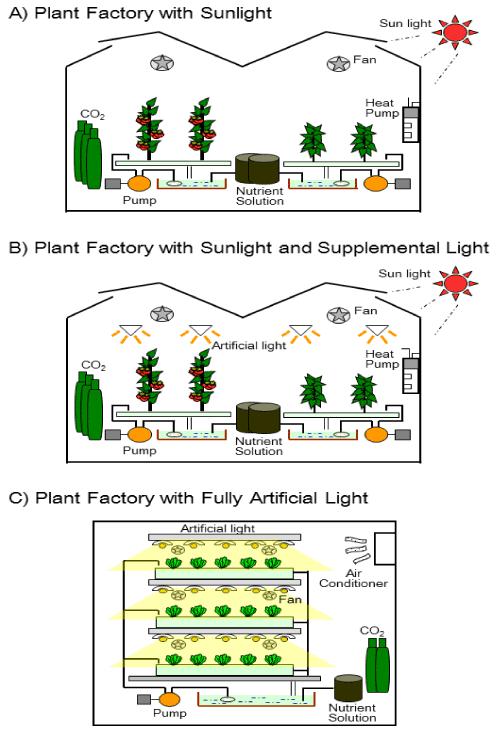

—— Plant factory with sunlight.

—— Plant factory with sunlight and supplemental light.

—— Plant factory with fully artificial light.

By adopting an independently developed Optical&Humidity climate control system, the unit can automatically control the cooling, heating, dehumidification mode, circulating and filtering the air to efficiently control.

Effectively control and maintain the customer's desired room temperature and humidity, so that the indoor can maintain the best climate suitable for plant growth or human comfort.

And through the energy-adjusting device, the system can provide free hot water while cooling (45℃)

Product Features

About Product

It has all the advantages of water source heat pump.

Fully Automatic Climate Management System

————

Fully automatic climate management system because of light-humidity,temperature sensor

Perfect Climate Control

————

Perfect climate control in summer and winter; temperature outside has no influence anymore.

Features

————

Cooling, heating, dehumidification , circulating and filtering the air,all mode in one system.

Add the Function

————

You can add the function of pre-heating and slow cooling, decide the most suitable environment according to your situation, and make your environment more accurate.

Offers all the Benefits

————

Offers all the benefits you need to let your plants flourish as never before.

Product Advantage

1.Intelligent Optical&Humidity climate control system, which determines the operation of cooling, heating or dehumidification according to the intensity of light, temperature and humidity.

2.The system can provide free hot water while cooling(45℃).

3.Advanced plate exchange technology,40% power saving(EER>4.5).

4.Most silent system,It is the quietest water-cooled air conditioning of its kind.

5.Perfect climate,It assures an optimal climate in your grow area.

6.Realises a homogenous distribution and a constant value of CO2.

7.European CE certification.

8. Patented product(patent No.ZL201510431905.9).

Application Range

1

Having Wide Application Range

Greenhouse industry, horticulture industry, urban greening industry, offices, apartments, yachts, and other areas that need to control light, humidity and temperature.

Production Photo

hicool@hicoolac.com

hicool@hicoolac.com